Happy Independence Day, folks! 🇮🇳

Today we talk about something we have all grown a little too dependent on – Shipping.

Not the free shipping you always desire on e-commerce platforms. Instead, the part of shipping that actually involves ships!

Ocean shipping accounts for more than 80% of the world’s international trade by volume and 70% by value. No wonder, the market is estimated to be more than $1T and shipping companies can together rake in as much as $150B of net income in a year.

Ocean shipping transports over 11B tons of cargo in a year. To put that into perspective, that’s 1.5 tonnes or 1500kg of freight per person. Yes, that’s the amount of influence ocean shipping has on our lives but most of it happens indirectly and for most of us, away from our eyes.

That’s also one of the reasons most of us know so less about it despite its immense influence on our lives.

While things to talk about the ocean shipping industry are as wide as the oceans themselves, today we’ll look at 3 aspects of the shipping industry – Containerization, Consolidation and Slow Steaming – that’ll let you understand shipping just a little more.

Containerization:

When you think about ocean shipping, a picture of a ship with lots of steel boxes sailing among endless blue water might appear in a normal person’s mind. Or maybe you’re like us and to this day, your head is still thinking about that little excavator that was trying to free the Evergiven ship that blocked the Suez Canal back in 2021!

Coming back to our steel boxes. These perfectly cuboidal structures are called, surprise surprise, containers! But as unassuming as they and their name might occur, they have been one of the most pivotal innovations not just for shipping but even for global trade as a whole. Here are some of the reasons why:

Efficiency:

Even a decade after the end of the second world war, before the advent of containers in the late 1950s, shipping cargo was handled piece by piece – a practice called break bulk shipping. Even imagining clusters of rice bags, boxes with wine bottles, and crates of mangoes all put loosely on the deck and tied with ropes gives an appalling feeling of inefficiency.

Loading and unloading of such break bulk cargo in ships used to take weeks. But all changed after a truck driver from America – Malcolm McLean pioneered the idea of using steel boxes already filled with cargo that could easily be put on and off the ship’s deck. What earlier took weeks could now be done in hours.

While the ability to quickly load and unload on the ship brought efficiency in time, the ability of the containers to be easily stacked onto each other brought a great deal of efficiency in space management.

Protection while Shipping:

These sturdy steel boxes also provided protection to the cargo from harsh weather on the seas. It also reduced the chances of theft which were high when earlier the cargo directly changed so many hands during the shipping process. There was a funny saying at that time, a dock worker’s wage is $20 per day and as many bottles of red wine as they can sneak out with.

International Standardisation:

One of the most amazing aspects and reasons for the success of containerization is that their size and shapes are standardized all across the globe. To be honest, that’s quite remarkable considering that we live in a world where countries can’t even decide upon what currency to use, plug types to use for sockets, the side of the road to drive on, or whether to use jet spray or toilet paper! (Well, although there’s no doubt that jet sprays are a far better option).

It is believed that 90% of the world’s container cargo is shipped in containers that are either 20 feet by 8 feet by 8 feet or twice as long, that is, 40*8*8 feet. This standardization is also the reason container volumes are often quoted in TEUs or Twenty-foot Equivalent Units.

Worth mentioning, the largest container ships as of today (2023) have a capacity of over 24,000 TEUs. While this number alone is remarkable, just 20 years ago, we had no ship that could carry even 10,000 TEUs!

Not just the size but even the design of the doors and hooks are the same and hence different types of cranes are not required at ports for loading and unloading.

Intermodal Operability:

The benefits of containerization are not just because of what they can do on ships and terminals, but also because of their intermodal operability. That is, these containers can be easily mounted on other modes of transport like trucks and trains, thus saving time and effort throughout the entire supply chain.

A manufacturer can pack the cargo in a container in the factory and the item inside can reach the customer at the other end of the world without ever having to be taken out of that very container. The next time you find yourself stuck in traffic behind a truck, do try to notice if the container and the trailer below are detachable!

While as simple as it might seem, containerization can arguably be one of the most important innovations of not just the 20th century but all of human history.

“Simplicity is the ultimate sophistication.”

– Leonardo da Vinci

Consolidation of Shipping Companies

The second trend in the shipping business that we discuss today is that of consolidation.

Running a container shipping business is an extremely capital-intensive business. The largest of container ships today cost well over $200M, add to that the fuel costs, wages for the crew, port fees, and maintenance costs – all this makes operating a shipping line a costly and operationally heavy business.

Hence, economies of scale play a very vital role in the industry. And that’s the reason we have seen a great deal of consolidation in the shipping industry. There has been lots of mergers and acquisition in the shipping business and when the smaller players failed, the existing big players quickly filled in the demand.

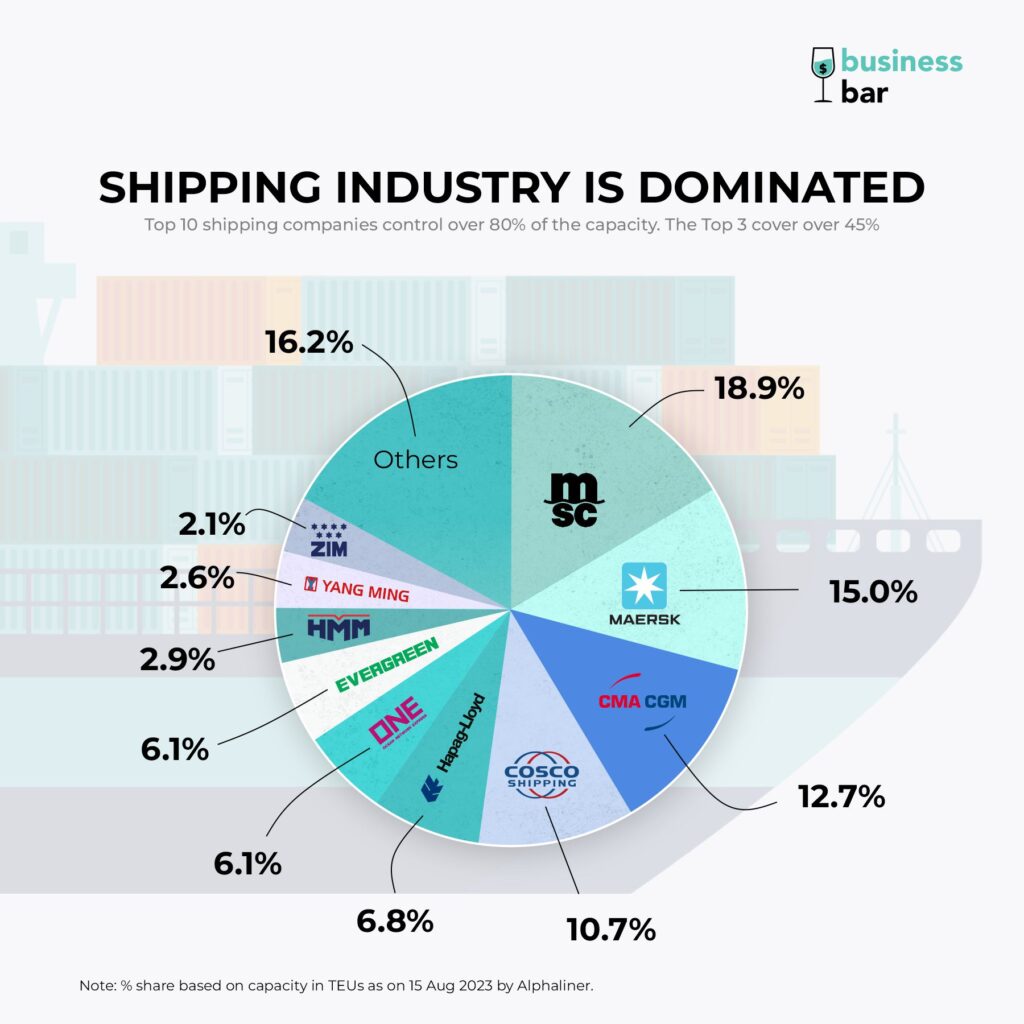

Around the turn of the century, the Top 10 shipping companies accounted for ~50% of the capacity, today the top 10 accounts for ~85% of the market.

In fact, the 3 biggest shipping lines, Italy-based MSC, the Danish company Maersk and the France-based CMA-CGM group together account for more than 45% of the capacity.

Experts believe that the end to market consolidation isn’t near and we could be seeing more of it in the future. Who knows if we might end up with a duopoly in the shipping line business just like the Airbus and Boeing Duopoly in the aircraft manufacturing business!

Slow Steaming

We saw how containerization reduced shipment time; a journey from Australia to Europe that took 70 days took only 34 days without increasing the ships’ speed.

If containerization was the biggest innovation that happened to shipping in the 20th century, then the biggest innovation in shipping to happen in the 21st century is slow steaming. While the former reduced travel times, slow steaming, as the name suggests, rather does the opposite.

Back in 2008, when oil prices were off the charts and consumer demand for goods plummeted due to the Global Financial Crisis, shipping companies faced great pressure. Their biggest cost component – fuel – was sky-high and their revenue was dropping due to low demand. Add to that the fact that orders for new ships take years to get delivered and so shipping companies were receiving deliveries of vessels even when demand was declining.

To navigate through this situation, a crew at Maersk came up with another simple idea. Just go slow.

Fuel consumption is exponentially related to the speed with which the ship cruises. Hence going slow would give significant cost savings. Before you start laughing at why no one did it before, let us tell you that running ships at speeds slower than what they are designed for can cause severe engine and hull damage, thus vanquishing all savings from fuel.

Nevertheless, the crew at Maersk reduced the ship’s cruising speed from the upper range of 22 knots (41 km/h) to 14-18 knots. Surprisingly, this worked and led to overall cost savings. Since then, it is now common practice for ships to go well below their top cruising speeds, and this is one of the reasons why shipping has been such a cheap way of transportation.

Of course, when the demand is high, ships would choose to rather go full speed and do as many trips as possible, but given the current overcapacity of vessels, slow steaming is a strategic move.

With technology, slow steaming can soon become smart steaming where ships would optimize speed for both cost savings and schedules of getting terminal access at ports.

Waters Ahead for Shipping Industry

Containerization, Consolidation and Slow-Steaming have made ocean shipping cheaper than ever. It costs less than ₹25 (30 cents) to send a box of shoes from a port in Vietnam to the port of Los Angels in the US. For an iPad, this cost will be half. That’s more than the cost of a single piece of chicken nugget in a McDonald’s in the USA!

That is not to say that there are no changes on the cards for the industry. Ships have a fair share in polluting the climate and figuring out greener ways to run ships is something that is underway. In 2021, ‘Tesla of the Seas’ set sail, which was a fully electric and crewless container ship. Although it costs 3x the usual freight rate, this green premium is expected to come down. Blockchain too, finds plenty of applications in the industry with the potential of removing the enormous amount of paperwork that is currently commonplace in the industry.

Shipping companies are also focusing on expanding their business in other parts of the supply chain. Maersk has decided to shift its focus away from shipping and toward more profitable lines of business, like air freight, trucking, warehousing, operating port terminals, and selling logistics software. The company aims to reinvent itself as a one-stop shop for every step of the supply chain. Many new-age companies are also trying to disrupt parts of the supply chain that aids the shipping business. Read our cover on the freight-forwarding startup – Flexport.

Ocean shipping has been the true enabler of a globalized world. Ocean shipping not only delivers products but also underpins the very idea of a connected world, where ideas, innovation, and prosperity can sail unencumbered across borders. Ocean shipping – shrinking the world but enlarging human choice!

Written and Researched by Priyesh Zalani